1: Brief Introduction Of 2507 duplex stainless steel

Alloy 2507 is a super duplex stainless steel with 25% chromium, 4% molybdenum, and 7% nickel designed for demanding applications which require exceptional strength and corrosion resistance, such as chemical process, petrochemical, and seawater equipment. The steel has excellent resistance to chloride stress corrosion cracking, high thermal conductivity and a low coefficient of thermal expansion. The high chromium, molybdenum, and nitrogen levels provide excellent resistance to pitting, crevice, and general corrosion.

The impact strength is also high. Alloy 2507 is not recommended for applications which require long exposures to temperatures above 570°F because of the risk of a reduction in toughness.

Corrosion Resistance:

General Corrosion:

★high chromium and molybdenum content of 2507 makes it extremely resistant to uniform corrosion by organic acids like formic and acetic acid.

★provides excellent resistance to inorganic acids, especially those containing chlorides.

★can be used in dilute hydrochloric acid.

★Pitting need not be a risk in the zone below the borderline in this figure, but crevices must be avoided.

Intergranural Corrosion:

★Low carbon content greatly lowers the risk of carbide precipitation at the grain boundaries during heat treatment.

★Is highly resistant to carbide-related intergranular corrosion.

Stress Corrosion Cracking:

★Duplex structure of 2507 provides excellent resistance to chloride stress corrosion cracking (SCC).

★Superior to 2205 in corrosion resistance and strength.

★2507 is especially useful in offshore oil and gas applications and in wells with either naturally high brine levels or where brine has been injected to enhance recovery.

Pitting Corrosion:

★Different testing methods can be used to establish the pitting resistance of steels in chloride-containing solutions.

Crevice Corrosion:

★Highly resistant to crevice corrosion.

Standards:

ASTM/ASME ...… A240 - UNS S32750

EURONORM...... 1.4410 - X2 Cr Ni MoN 25.7.4

AFNOR......... Z3 CN 25.06 Az

Other Grades:

201,202,21-4N,301,302,301L,303,303Se,304,304L,304H,304LN,304N,305,S38400,308,309,309S,310,310s,

316,316L,316H,316Ti,316N,316LN,317,317L,317LMN,317LN,321,321H,347,347H,S3100,S31803,S3205,

S32304,S31200,S31260,S32507,405,409,429,430,430F,434,444,403,410S,410,416,420,420F,431F,440A

440B,440C,440F,610,630,631,632,635,660,Alloy 200,Monel 400 ,Alloy K-500 ,Inconel 600 , Incconel 601,

Inconel 625 , Inconel 718 , Alloy 800 ,Alloy 800H,Alloy 800HT,Inconel 825,Alloy 276, Alloy 20, Alloy 59

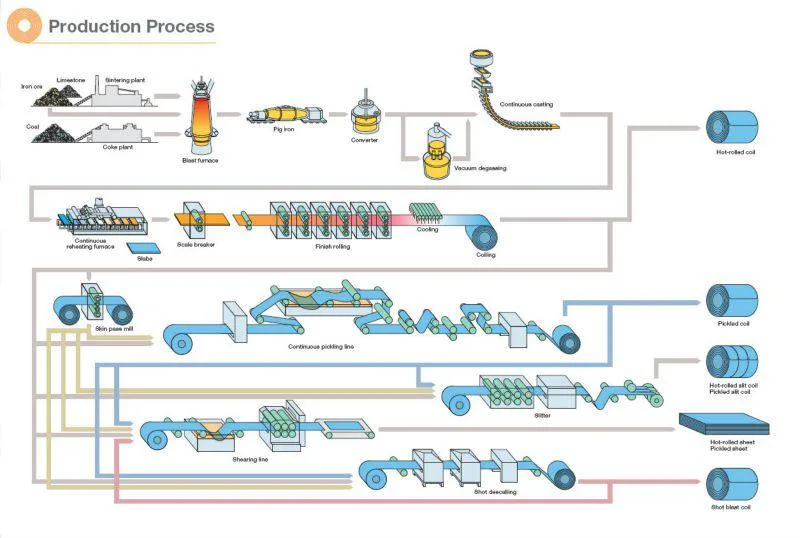

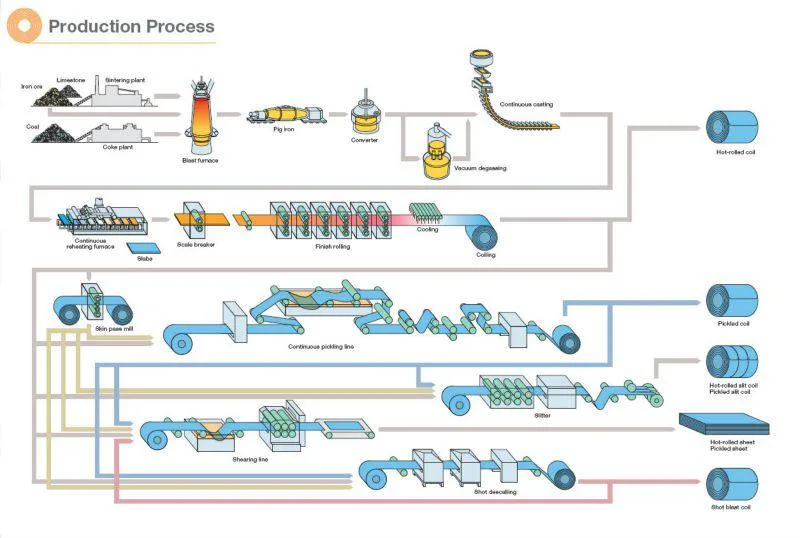

2: Stainless Steel Coil Process

3: Stainless Steel Coil Package

4: About us

Tianjin Zhongyantiancheng Steel Co.,Ltd(short for ZYTC ) is a professional manufacturer and exporter of steel products in China, located in Tianjin Beichen District, having the biggest port in North China.

With 20 years of development, the group has become the leader in steel, product variety, complete specifications and so on in North China market, large inventories more than 100,000 tons are maintained all the time.

ZYTC is specialized in steel products, especially Stainless steel pipe,Stainless steel bar,Stainless steel plate (TG,KSK,BG,Krupp), Round bar(SHOUGANG,DAYE), Spiral pipe(LIDA), Aluminum steel plate,Aluminum pipe ,Copper and so on .

ZYTC has cooperated with Tianjin Seamless Steel Tube Plant(TPCO), Baotou Steel Pipe Plant, Chengdu Steel Pipe Plant, Anshan Steel Pipe Plant,Baoshan Steel Pipe Plant and other steel pipe plants.Round bar cooperated with Beijing shougang goup,Tonggang steel group, Daye steel bar group ,Benxi bengang group an so on , Baotai titanium group,Baoji Lixing group,Stainless steel plate cooperated with Shanxi TAIGANG Steel Plate grouop,Baogang group,Shanghai Kelubo group ,and Puxiang steel group. all these corporations mentioned above are our shareholder partners.

ZYTC principle is: supplying the best products and service,being the best supplier.

The company can make steel product according to particular specifications and materials. ZYTC will perfect our quality management system and supply products of high quality to our customers.

We are all looking forward to establishing business relationships with customers all over the world!

5: Why choose us

★ More than 20 years experience in stainless and aluminum steel fields.

★ Samples available.

★ Specialist metallurgic advice and flexible service.

★ High level of expertise, in-depth product knowledge.

★Competitive price, high quality,rich experiences and high reputation

★Delivered on time.

★ Good after-sale service.

★ Well recognized and trusted by customers.

Alloy 2507 is a super duplex stainless steel with 25% chromium, 4% molybdenum, and 7% nickel designed for demanding applications which require exceptional strength and corrosion resistance, such as chemical process, petrochemical, and seawater equipment. The steel has excellent resistance to chloride stress corrosion cracking, high thermal conductivity and a low coefficient of thermal expansion. The high chromium, molybdenum, and nitrogen levels provide excellent resistance to pitting, crevice, and general corrosion.

The impact strength is also high. Alloy 2507 is not recommended for applications which require long exposures to temperatures above 570°F because of the risk of a reduction in toughness.

Corrosion Resistance:

General Corrosion:

★high chromium and molybdenum content of 2507 makes it extremely resistant to uniform corrosion by organic acids like formic and acetic acid.

★provides excellent resistance to inorganic acids, especially those containing chlorides.

★can be used in dilute hydrochloric acid.

★Pitting need not be a risk in the zone below the borderline in this figure, but crevices must be avoided.

Intergranural Corrosion:

★Low carbon content greatly lowers the risk of carbide precipitation at the grain boundaries during heat treatment.

★Is highly resistant to carbide-related intergranular corrosion.

Stress Corrosion Cracking:

★Duplex structure of 2507 provides excellent resistance to chloride stress corrosion cracking (SCC).

★Superior to 2205 in corrosion resistance and strength.

★2507 is especially useful in offshore oil and gas applications and in wells with either naturally high brine levels or where brine has been injected to enhance recovery.

Pitting Corrosion:

★Different testing methods can be used to establish the pitting resistance of steels in chloride-containing solutions.

Crevice Corrosion:

★Highly resistant to crevice corrosion.

Standards:

ASTM/ASME ...… A240 - UNS S32750

EURONORM...... 1.4410 - X2 Cr Ni MoN 25.7.4

AFNOR......... Z3 CN 25.06 Az

Other Grades:

201,202,21-4N,301,302,301L,303,303Se,304,304L,304H,304LN,304N,305,S38400,308,309,309S,310,310s,

316,316L,316H,316Ti,316N,316LN,317,317L,317LMN,317LN,321,321H,347,347H,S3100,S31803,S3205,

S32304,S31200,S31260,S32507,405,409,429,430,430F,434,444,403,410S,410,416,420,420F,431F,440A

440B,440C,440F,610,630,631,632,635,660,Alloy 200,Monel 400 ,Alloy K-500 ,Inconel 600 , Incconel 601,

Inconel 625 , Inconel 718 , Alloy 800 ,Alloy 800H,Alloy 800HT,Inconel 825,Alloy 276, Alloy 20, Alloy 59

2: Stainless Steel Coil Process

3: Stainless Steel Coil Package

4: About us

Tianjin Zhongyantiancheng Steel Co.,Ltd(short for ZYTC ) is a professional manufacturer and exporter of steel products in China, located in Tianjin Beichen District, having the biggest port in North China.

With 20 years of development, the group has become the leader in steel, product variety, complete specifications and so on in North China market, large inventories more than 100,000 tons are maintained all the time.

ZYTC is specialized in steel products, especially Stainless steel pipe,Stainless steel bar,Stainless steel plate (TG,KSK,BG,Krupp), Round bar(SHOUGANG,DAYE), Spiral pipe(LIDA), Aluminum steel plate,Aluminum pipe ,Copper and so on .

ZYTC has cooperated with Tianjin Seamless Steel Tube Plant(TPCO), Baotou Steel Pipe Plant, Chengdu Steel Pipe Plant, Anshan Steel Pipe Plant,Baoshan Steel Pipe Plant and other steel pipe plants.Round bar cooperated with Beijing shougang goup,Tonggang steel group, Daye steel bar group ,Benxi bengang group an so on , Baotai titanium group,Baoji Lixing group,Stainless steel plate cooperated with Shanxi TAIGANG Steel Plate grouop,Baogang group,Shanghai Kelubo group ,and Puxiang steel group. all these corporations mentioned above are our shareholder partners.

ZYTC principle is: supplying the best products and service,being the best supplier.

The company can make steel product according to particular specifications and materials. ZYTC will perfect our quality management system and supply products of high quality to our customers.

We are all looking forward to establishing business relationships with customers all over the world!

5: Why choose us

★ More than 20 years experience in stainless and aluminum steel fields.

★ Samples available.

★ Specialist metallurgic advice and flexible service.

★ High level of expertise, in-depth product knowledge.

★Competitive price, high quality,rich experiences and high reputation

★Delivered on time.

★ Good after-sale service.

★ Well recognized and trusted by customers.