TOKO Duplex Stainless Steel AWS E2209

| AWS E2209-15 | According with GB E2209-15 Corresponding with AWS E2209-15 | ||||||||||||||||||||||

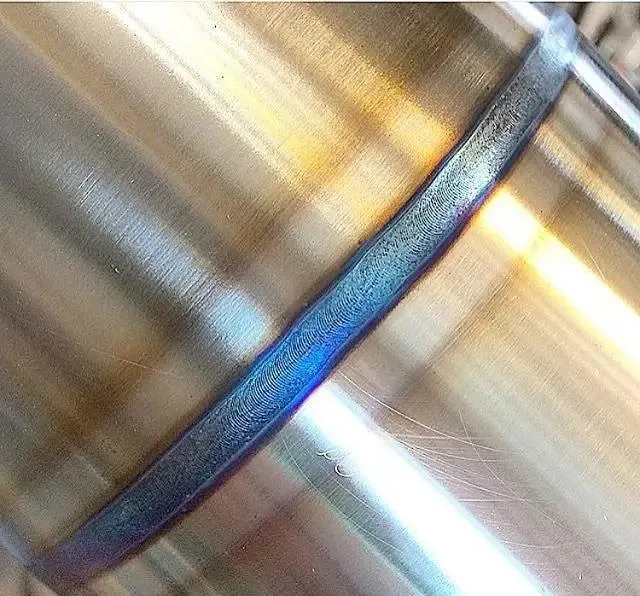

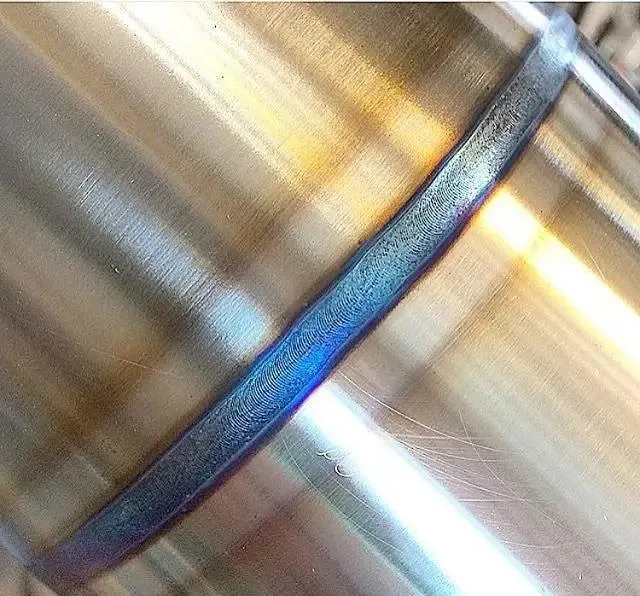

Introduction: RF-E2209-15 is a kind of ultra-low-carbon dual-phase stainless steel electrode with basic coating. The deposited metal contains 40%-50% ferrite. It has excellent mechanical properties and corrosion-resistance, especially reliable chloride corrosion-resistance and high pitting corrosion-resistance. It has excellent welding performance. DCRP (Direct Current Reversed Polarity). All-position welding. | |||||||||||||||||||||||

Uses: Used for welding ultra-low-carbon dual-phase stainless steel like 00Cr22Ni5Mo3N, SAF2205, etc. | |||||||||||||||||||||||

Chemical Composition of Deposited Metal (%)

| |||||||||||||||||||||||

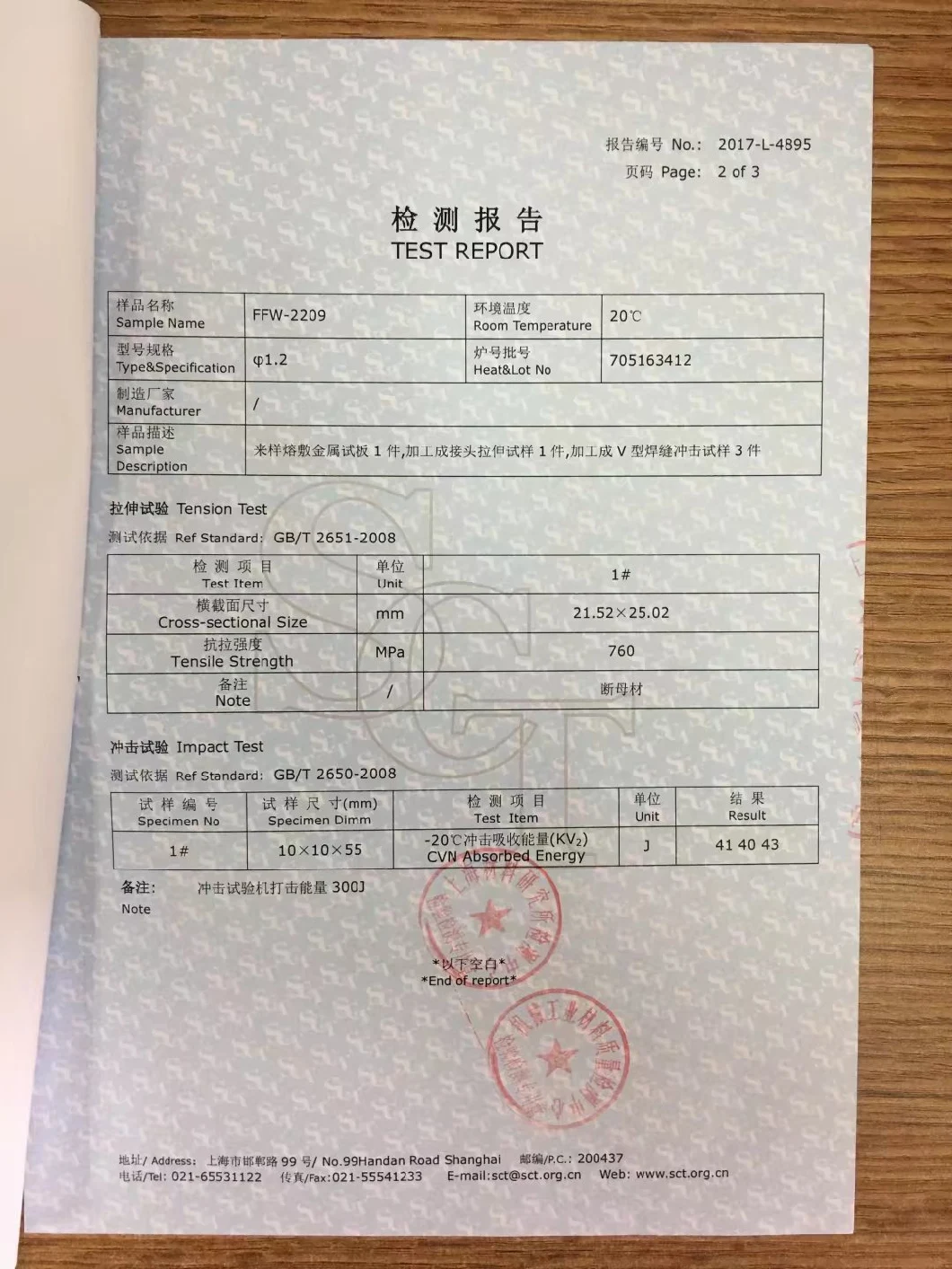

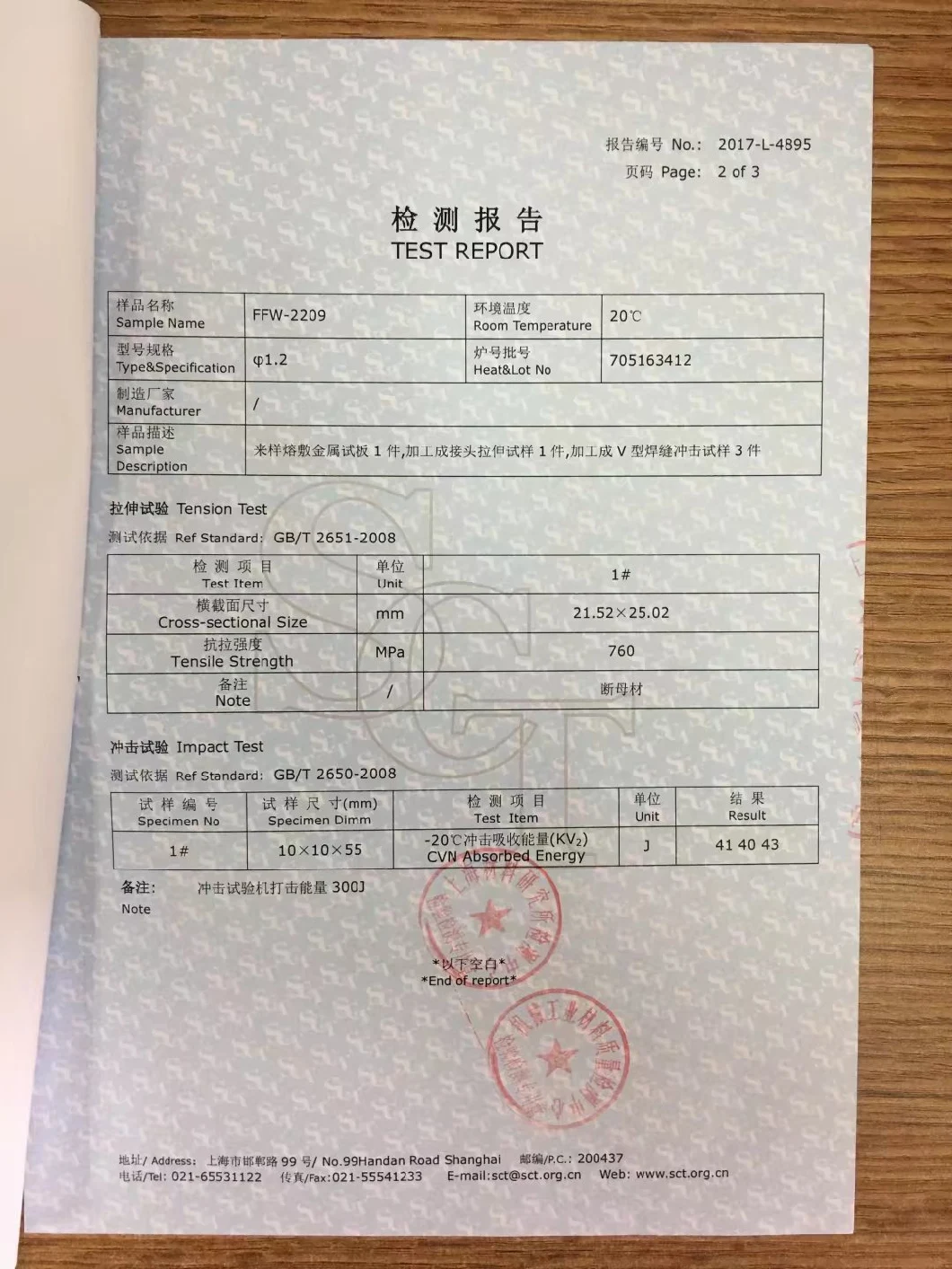

Mechanical Properties of Deposited Metal

| |||||||||||||||||||||||

Reference Current (AC, DC+)

| |||||||||||||||||||||||

Instructions: 1.The electrodes should be baked under about 350ºC for 1.5 hours before welding. 2.When welding, the current should not be too strong. | |||||||||||||||||||||||