1: Brief Introduction Of 304 stainless steel

Alloy 304 a T-300 series stainless steel austenitic, which has a minimum of 18% chromium and 8% nickel. Type 304 has a

maximum carbon of 0.07% . It is the standard "18/8 stainless" that is commonly found in pans and cooking tools. Alloy 304

is the most versatile and widely used alloy in the stainless steel family. Ideal for a wide variety of home and commercial

applications, Alloy 304 exhibits excellent corrosion resistance and has a high ease of fabrication, outstanding formability.

The austenitic stainless steels are also considered to be the most weldable of the high-alloy steels and can be welded by

all fusion and resistance welding processes.

Corrosion Resistance:

★Resistance to moderately aggressive organic acids is a result of the 9 to 11% nickel that the 304 alloys contain.

★Resistance to corrosion in oxidizing environments is a result of the 18 to 19% chromium that the 304 alloys contain.

★The 304, 304L, and 304H may be considered to perform uniformly in most corrosive environments.

Heat Resistance:

★Continuous use of 304 in the 800-1580°F range is not recommended if subsequent aqueous corrosion resistance is important.

Machinability:

★The use of chip breakers is advised since the chips can be stringy. Stainless steel work harden rapidly, heavy positive

feeds, sharp tooling, and a rigid set-up should be used.of cut below the work-hardened layer resulting from the previous passes.

★Good oxidation resistance in intermittent service to 1600°F and in continuous service to 1690°F.

Standards:

ASTM/ASME: UNS S30400 / S30403

EURONORM: 1.4301 / 1.4303

AFNOR: Z5 CN 18.09 / Z2 CN 18.10

DIN: X5 CrNi 18 10 / X2 CrNi 19 11

Other Grades:

201,202,21-4N,301,302,301L,303,303Se,304,304L,304H,304LN,304N,305,S38400,308,309,309S,310,310s,

316,316L,316H,316Ti,316N,316LN,317,317L,317LMN,317LN,321,321H,347,347H,S3100,S31803,S3205,

S32304,S31200,S31260,S32507,405,409,429,430,430F,434,444,403,410S,410,416,420,420F,431F,440A

440B,440C,440F,610,630,631,632,635,660,Alloy 200,Monel 400 ,Alloy K-500 ,Inconel 600 , Incconel 601,

Inconel 625 , Inconel 718 , Alloy 800 ,Alloy 800H,Alloy 800HT,Inconel 825,Alloy 276, Alloy 20, Alloy 59

2: Chemical Composition

| Tianjin Zhongyantiancheng Steel Co.,Ltd | ||||

| Commodity | Stainless Steel Bar/Stainless Steel Round Bar/Stainless Steel Rod | |||

| Material | 304 | |||

| Standard | GB | JIS | ASTM/ASME | DIN |

| 06Cr19Ni10 | SUS304 | 304 | 1.4301 | |

| Chemical Composition | C | Mn | P | S |

| <=0.08 | <=2.00 | <=0.045 | <=0.03 | |

| Si | Cr | N | Ni | |

| <=1.00 | 18-20 | NO | 8--10 | |

| Diameter | 4mm-720mm | |||

| Length | Cut as your requirement | |||

| Surface | Black/Bright | |||

| manufacture | Hot Rolled/Cold Drawn/Forged | |||

| Packing | Packed in bundles with standard export sea-worthy package | |||

| Delivery Time | Within 15 working days, according to customers' quantities | |||

| Quality | High Quality.SGS inspection is accepted if needed | |||

| Place of Origin | Tianjin | |||

| Productivity | 500 MT/Month | |||

| Payment | T/T,L/C | |||

| MOQ | 1 MT | |||

| Application | Foodstuff, Gas, metallurgy, biology, electron, chemical etc. | |||

| Note | We can also do other materials | |||

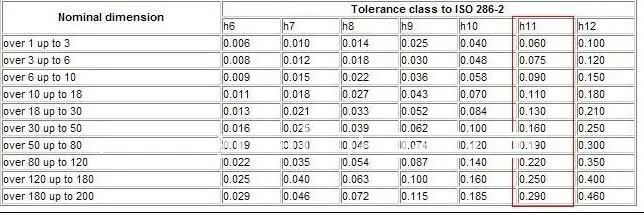

4: 304 Stainless Steel Round Bar Diameter Tolerance

5: Company Introduction