Stasndard:ASTM A240,JIS4304-2005,ASTM A167,EN10088-2-2005, GB/T3280-2007, etc

Material: 310S,310,309,309S,316,316L,316Ti,317,317L,321,321H,347,347H,304,304L,

302,301,201,202,403,405,409,409L,410,410S,420,430,631,904L,Duplex,etc

Surface:

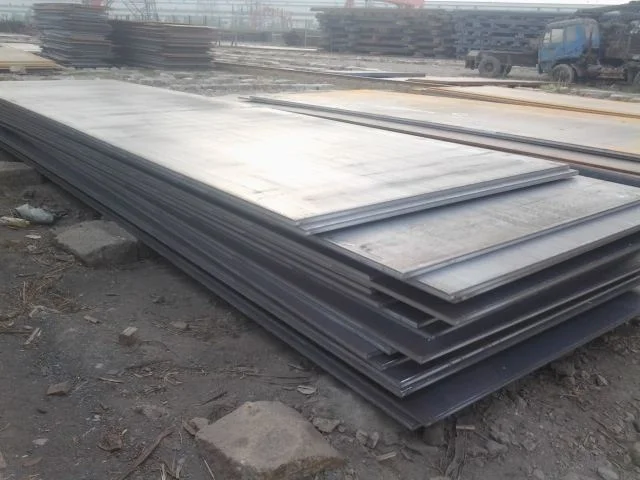

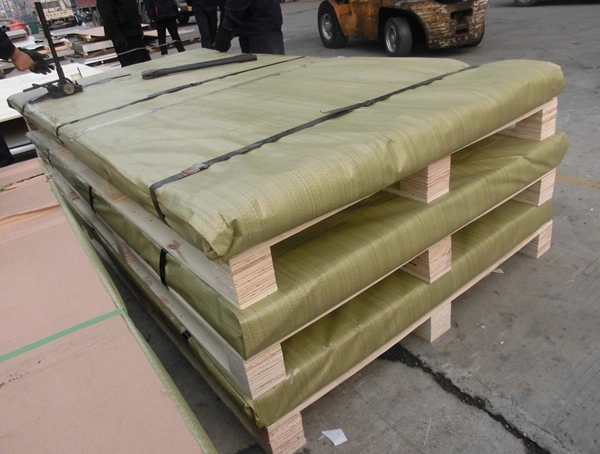

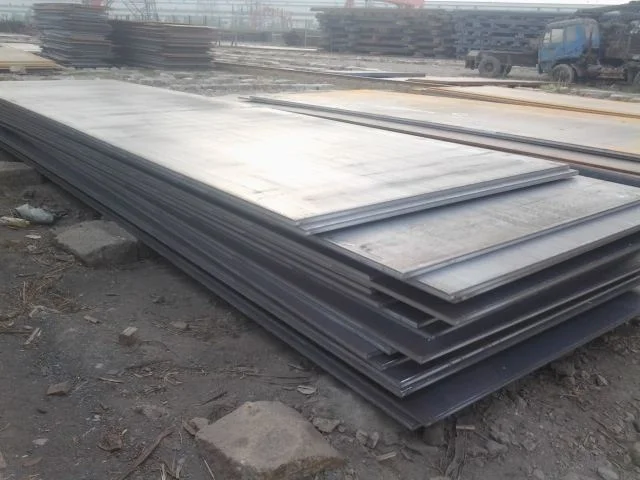

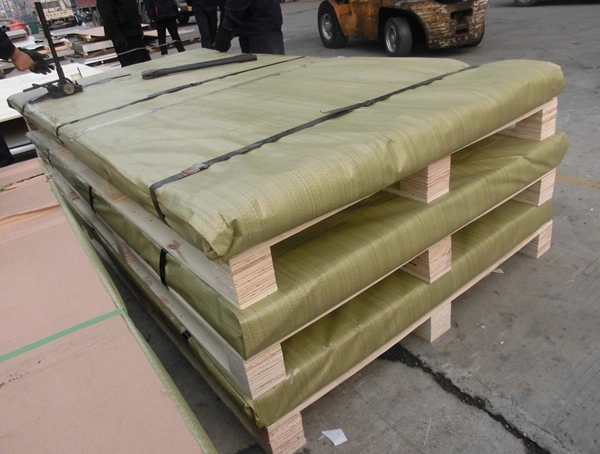

Varnished,PE coated,galvanized,clean,Galvanized ,blasting and oil coated or as requested.

Application: used in Building Construction,Bridge,Architecture,Vehicles Components,

hipping,High pressure container,Boiler,Large Structure steel etc.

Advantages:

1.20 + years of production experience at your service.

2. The fastest delivery

3. The lowest price

4. Most comprehensive standards and materials for your choice.

5.100% export.

6. Our products EXPORT to Africa, Oceania, mid east, eastern Asia, Western Europe etc.

Chemical composition

Surface treatment:

Material: 310S,310,309,309S,316,316L,316Ti,317,317L,321,321H,347,347H,304,304L,

302,301,201,202,403,405,409,409L,410,410S,420,430,631,904L,Duplex,etc

Surface:

Varnished,PE coated,galvanized,clean,Galvanized ,blasting and oil coated or as requested.

Application: used in Building Construction,Bridge,Architecture,Vehicles Components,

hipping,High pressure container,Boiler,Large Structure steel etc.

Advantages:

1.20 + years of production experience at your service.

2. The fastest delivery

3. The lowest price

4. Most comprehensive standards and materials for your choice.

5.100% export.

6. Our products EXPORT to Africa, Oceania, mid east, eastern Asia, Western Europe etc.

Chemical composition

Grade | C ≤ | Si ≤ | Mn ≤ | P ≤ | S ≤ | Ni ≤ | Cr ≤ |

201 | 0.12 | 0.75 | 7.00 | 0.045 | 0.045 | 1.00-1.28 | 13.70-15.70 |

202 | 0.15 | 1.00 | 2.25 | 0.045 | 0.045 | 4.07-4.17 | 14.00-16.00 |

304 | 0.08 | 0.75 | 2.00 | 0.045 | 0.03 | 8.00-11.00 | 18.00-20.00 |

304L | 0.035 | 0.75 | 2.00 | 0.045 | 0.03 | 8.00-13.00 | 18.00-20.00 |

309 | 0.15 | 0.75 | 2.00 | 0.045 | 0.03 | 12.00-15.00 | 22.00-24.00 |

310S | 0.08 | 1.50 | 2.00 | 0.045 | 0.03 | 19.00-22.00 | 24.00-26.00 |

316 | 0.08 | 1.00 | 2.00 | 0.045 | 0.03 | 10.00-14.00 | 16.00-18.00 |

316L | 0.035 | 0.75 | 2.00 | 0.045 | 0.03 | 10.00-15.00 | 16.00-18.00 |

321 | 0.04-0.10 | 0.75 | 2.00 | 0.045 | 0.03 | 9.00-13.00 | 17.00-20.00 |

405 | 0.08 | 0.75 | 1.00 | 0.045 | 0.03 | 0.06 | 11.5-13.5 |

409 | 0.089 | 1.00 | 1.00 | 0.045 | 0.05 | 0.06 | 10.50-11.75 |

410 | 0.15 | 0.75 | 1.00 | 0.045 | 0.03 | 0.06 | 11.5-13.5 |

420 | 0.16-0.25 | 1.00 | 1.00 | 0.040 | 0.03 | 0.06 | 12.00-14.00 |

430 | 0.12 | 0.75 | 1.00 | 0.045 | 0.03 | 0.06 | 16.00-18.00 |

904L | 0.02 | 1.0 | 2.00 | 0.045 | 0.03 | 23.00-28.00 | 19.00-23.00 |

| Surface | Definition | Application |

| NO.1 | The surface finished by heat treatment and pickling or processes corresponding there to after hot rolling. | Chemical tank, pipe. |

| 2B | Those finished, after cold rolling, by heat treatment, pickling or other equivalent treatment and lastly by cold rolling to given appropriate luster. | Medical equipment, Food industry, Construction material, Kitchen utensils. |

| NO.3 | Those finished by polishing with No.100 to No.120 abrasives specified in JIS R6001. | Kitchen utensils, Building construction |

| NO.4 | Those finished by polishing with No.150 to No.180 abrasives specified in JIS R6001. | Kitchen utensils, Building construction, Medical equipment. |

| HL | Those finished polishing so as to give continuous polishing streaks by using abrasive of suitable grain size | Building Construction. |

| BA | Those processed with bright heat treatment after cold rolling | Kitchen utensils, Electric equipment, Building construction. |

| 8K | Shinning like a mirror | Building construction |