321 (UNS S32100) is titanium stabilized austenitic stainless steel plate with good general corrosion resistance. It has

excellent resistance to intergranular corrosion after exposure to temperatures in the chromium carbide precipitation range

of 800 - 1500°F (427 - 816°C). The alloy resists oxidation to 1500°F (816°C) and has higher creep and stress rupture

properties than alloys 304 and 304L. It also possesses good low temperature toughness.

Alloy 321H (UNS S 32109) stainless steel plate is the higher carbon (0.04 - 0.10) version of the alloy. It was developed for

enhanced creep resistance and for higher strength at temperatures above 1000oF (537°C). In most instances, the carbon

content of the plate enables dual certification.

Alloy 321 stainless steel plate cannot be hardened by heat treatment, only by cold working. It can be easily welded and

processed by standard shop fabrication practices.

Alloy 321 stainless steel plate exhibits good general corrosion resistance that is comparable to 304. It was developed for

use in the chromium carbide precipitation range of 1800 - 1500°F (427 - 816°C) where un-stabilized alloys such as 304

are subject to intergranular attack.

The alloy can be used in most diluted organic acids at moderate temperatures and in pure phosphoric acid at lower

temperatures and up to 10% diluted solutions at elevated temperatures. Alloy 321 resists polythionic acid stress corrosion

cracking in hydrocarbon service. It can also be utilized in chloride or fluoride free caustic solutions at moderate temperatures.

Alloy 321 stainless steel plate does not perform well in chloride solutions, even in small concentrations, or in sulfuric acid service.

Other Grades:

201,202,21-4N,301,302,301L,303,303Se,304,304L,304H,304LN,304N,305,S38400,308,309,309S,310,310s,

316,316L,316H,316Ti,316N,316LN,317,317L,317LMN,317LN,321,321H,347,347H,S3100,S31803,S3205,

S32304,S31200,S31260,S32507,405,409,429,430,430F,434,444,403,410S,410,416,420,420F,431F,440A

440B,440C,440F,610,630,631,632,635,660,Alloy 200,Monel 400 ,Alloy K-500 ,Inconel 600 , Incconel 601,

Inconel 625 , Inconel 718 , Alloy 800 ,Alloy 800H,Alloy 800HT,Inconel 825,Alloy 276, Alloy 20, Alloy 59

| Tianjin Zhongyantiancheng Steel Co.,Ltd | ||||

| Commodity | Stainless Steel Flat Bar | |||

| Material | 321 | |||

| Standard | GB | JIS | ASTM/ASME | DIN |

| 06Cr18Ni11Ti | SUS321 | 321 | 1.4541 | |

| Chemical Composition | C | Mn | P | S |

| <=0.08 | <=2.00 | <=0.045 | <=0.03 | |

| Si | Cr | N | Ni | |

| <=1.00 | 17--19 | <=0.10 | 9.0-12.0 | |

| Thickness | 3mm-30mm | |||

| Width | 10mm-300mm | |||

| Length | Produce as customers' request | |||

| Surface | No.1/HL/Birght | |||

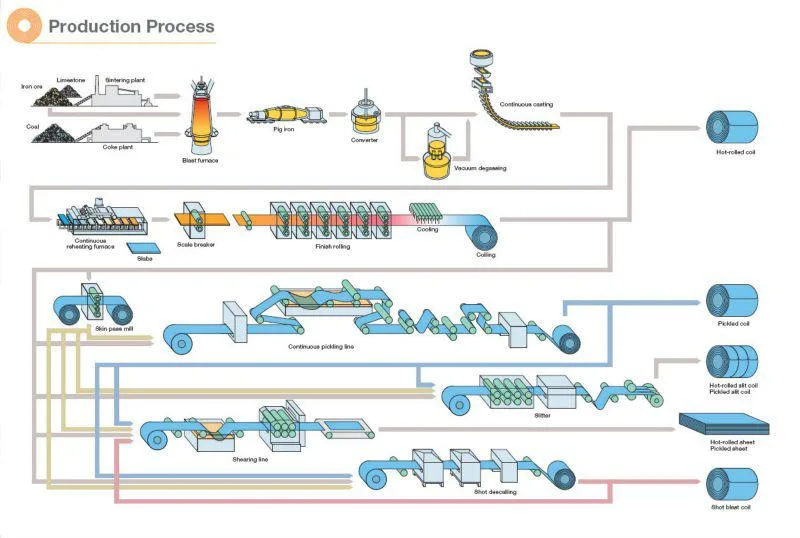

| manufacture | Hot Rolled | |||

| Packing | Packed in bundles with standard export sea-worthy package | |||

| Delivery Time | Within 15 working days, according to customers' quantities | |||

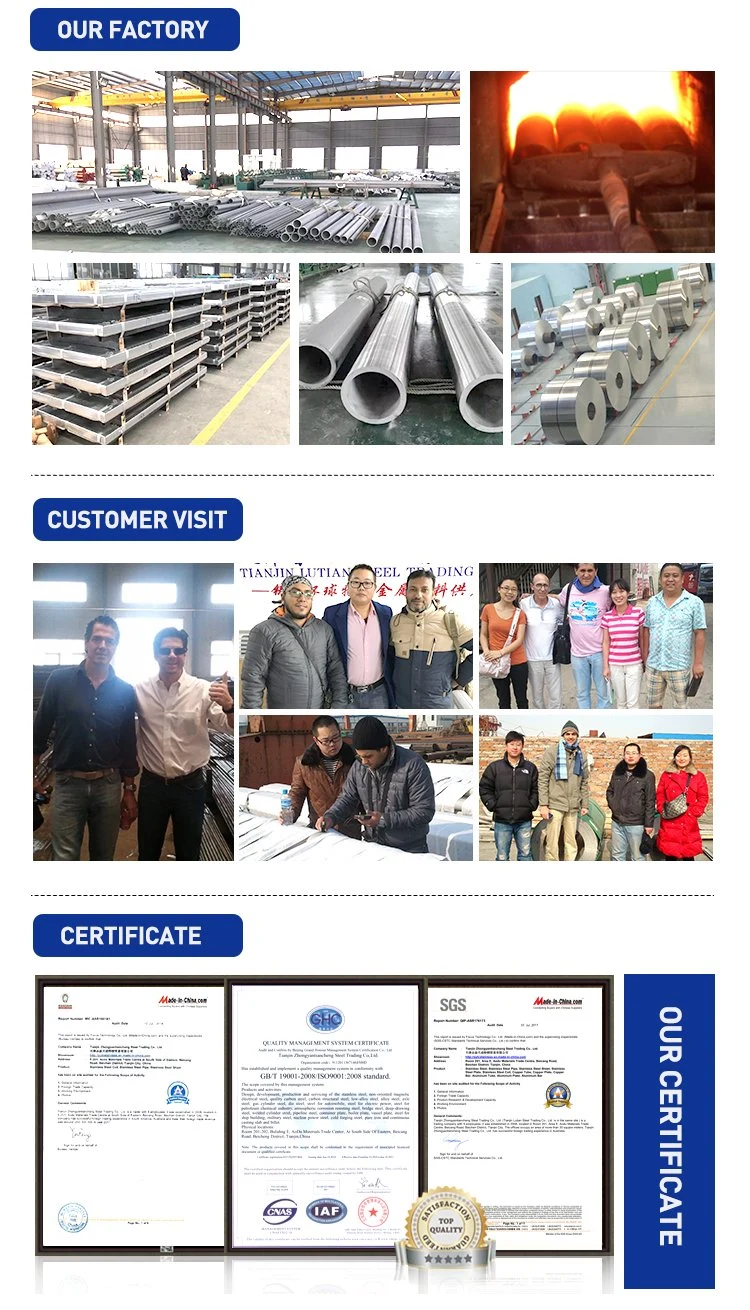

| Quality | High Quality.SGS inspection is accepted if needed | |||

| Place of Origin | Tianjin | |||

| Productivity | 500 MT/Month | |||

| Payment | T/T,L/C | |||

| MOQ | 1 MT | |||

| Application | Foodstuff, Gas, metallurgy, biology, electron, chemical etc. | |||

4: Package & Shipping

5: Company Introduction

6: Contact Us