What is 310/310S Stainlesss Steel?

Grade 310, combining excellent high temperature properties with good ductility and weldability, is designed for high temperature service. It resists oxidation in continuous service at temperatures up to 1150 °C provided reducing sulphur gases are not present. It is also used for intermittent service at temperatures up to 1040 °C.

Grade 310S (UNS S31008) is used when the application environment involves moist corrodents in a temperature range lower than that which is normally considered "high temperature" service. The lower carbon content of 310S does reduce its high temperature strength compared to 310.

| Stainless steel grade and chemical composition(%) |

| Grade | C | Si | Mn | P≤ | S≤ | Cr | Ni | Mo | N |

| 201 | ≤0.15 | ≤1.00 | 5.5-7.5 | 0.06 | 0.03 | 16-18 | 3.5-5.5 | ---- | ≤0.25 |

| 202 | ≤0.15 | ≤1.00 | 7.5-10.0 | 0.06 | 0.03 | 17-19 | 4-6 | ---- | ≤0.25 |

| 301 | ≤0.15 | ≤1.00 | ≤2.00 | 0.045 | 0.03 | 16-18 | 6-8 | ---- | ≤0.10 |

| 304 | ≤0.08 | ≤1.00 | ≤2.00 | 0.045 | 0.03 | 18-20 | 8-10.5 | ---- | ---- |

| 304L | ≤0.03 | ≤1.00 | ≤2.00 | 0.045 | 0.03 | 18-20 | 8-12 | ---- | ---- |

| 309 | ≤0.2 | ≤1.00 | ≤2.00 | 0.045 | 0.03 | 22-24 | 12-15 | ---- | ---- |

| 309S | ≤0.08 | ≤1.00 | ≤2.00 | 0.045 | 0.03 | 22-24 | 12-15 | ---- | ---- |

| 310 | ≤0.25 | ≤1.00 | ≤2.00 | 0.045 | 0.03 | 24-26 | 19-22 | ---- | ---- |

| 310S | ≤0.08 | ≤1.00 | ≤2.00 | 0.045 | 0.03 | 24-26 | 19-22 | ---- | ---- |

| 316 | ≤0.08 | ≤1.00 | ≤2.00 | 0.045 | 0.03 | 16-18 | 10-14 | 2-3 | ---- |

| 316L | ≤0.03 | ≤1.00 | ≤2.00 | 0.045 | 0.03 | 16-18 | 10-14 | 2-3 | ---- |

| 316H | 0.04-0.1 | ≤1.00 | ≤2.00 | 0.045 | 0.03 | 16-18 | 10-14 | 2-3 | ---- |

| 316Ti | ≤0.08 | ≤1.00 | ≤2.00 | 0.045 | 0.03 | 16-18 | 10-14 | 2-3 | ≤0.10 |

| 317 | ≤0.08 | ≤1.00 | ≤2.00 | 0.045 | 0.03 | 18-20 | 11-15 | 3-4 | ---- |

| 317L | ≤0.03 | ≤1.00 | ≤2.00 | 0.045 | 0.03 | 18-20 | 11-15 | 3-4 | ---- |

| 321 | ≤0.08 | ≤1.00 | ≤2.00 | 0.045 | 0.03 | 17-19 | 9-12 | ---- | ≤0.10 |

| 321H | 0.04-0.1 | ≤1.00 | ≤2.00 | 0.045 | 0.03 | 17-19 | 9-12 | ---- | ≤0.10 |

| 409 | ≤0.08 | ≤1.00 | ≤1.00 | 0.045 | 0.03 | 10.5-11.7 | ≤0.50 | ---- | ---- |

| 410 | ≤0.15 | ≤1.00 | ≤1.00 | 0.04 | 0.03 | 11.5-13.5 | ( ≤0.75) | ---- | ---- |

| 420 | ≥0.15 | ≤1.00 | ≤1.00 | 0.04 | 0.03 | 12-14 | ---- | ---- | ---- |

| 430 | ≤0.12 | ≤1.00 | ≤1.00 | 0.04 | 0.03 | 16-18 | ---- | ---- | ---- |

Product Grade | ||

| 300 series | 301,304,304L,309,309S,310,310S,310MoLN,316, 316L,316LN,317,317L,321,321H,330,347H | |

| 400 series | 403, 405, 409, 409L, 410, 410L , 420, 429 , 430, 431, 434 , 444 | |

| 600 Sreies | 630, 631, 632, 633, 635, 660 | |

| Super Stainless Steel | 904L, 253MA, 254MO, 654MO | |

| Duplex Stainless Steel | S32304 , S32550 , S31803 , S32750, S32760 | |

| Product Information | |

| Thickness | Up to 16mm |

| Width | 1000, 1219, 1250, 1500 mm, or as your requirements |

| Surface | 2B, BA, No.1, No.4, No.8, HL, 5K,Mirror etc |

| Productivity | 4000MT / Month |

| Standard | ASTM A240, GB/T3280-2007, JIS4304-2005, ASTM A167, EN10088-2-2005,etc |

| Payment Term | |

| Payment | T/T, irrevocable L/C at sight |

| Delivery Time | 7-10days, according to customers' quantities |

| Port | Tianjin Port |

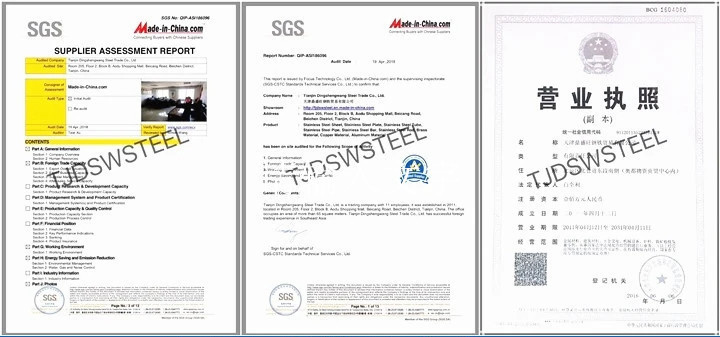

| Quality | High Quality.SGS inspection is accepted if needed |

| MTC | Mill Test Certificate is supplied with shipment, Third Part Inspection is acceptable |

| Certificate | ISO, SGS, and third part inspection. |

| Package: | Standard export seaworthy package,suit for all kinds of transport,or as required. |

Tianjin Dingshengwang Steel Co., Ltd. is a professional stainless steel enterprise integrating producing,

processing and marketing as a whole.

Our business range is Hot rolled and Cold rolled stainless steel coil,sheet,strip of grade 304, 316L, 321,

330, 904L, 2205, etc. In surface finish of No.4, Mirror 8K, Hair Line,ScotchBrite, Ti-golden and Color coated,

Embossed, Etched.

Welcome friends all over the world to join us. We will offer our best cooperation to meet your requirements.

We take the good faith operation tenet and strive to become your long-term reliable supplier.

Available surface for 201 304 304L 316 316L 310S 409 430 cold rolled stainless steel coil price:

| Fnish | Definition | Application |

| 2B | Those finished, after cold rolling, by heat treatment, pickling or other equivalent treatment and lastly by cold rolling to given appropriate luster. | Medical equipment, Food industry, Construction material, Kitchen utensils. |

BA/8K mirror | Those processed with bright heat treatment after cold rolling. | Kitchen utensils, Electric equipment, Building construction. |

| NO.3 | Those finished by polishing with No.100 to No.120 abrasives specified in JIS R6001. | Kitchen utensils, Building construction. |

| NO.4 | Those finished by polishing with No.150 to No.180 abrasives specified in JIS R6001. | Kitchen utensils, Building construction, Medical equipment. |

| Hairline | Those finished polishing so as to give continuous polishing streaks by using abrasive of suitable grain size. | Building Construction. |

| NO.1 | The surface finished by heat treatment and pickling or processes corresponding there to after hot rolling. | Chemical tank, pipe. |