1: Brief Introduction Of 405 stainless steel

405(UNS S40500)The chromium content in grade 405 stainless steel is 12%. The below datasheet provides

an overview of grade 405 stainless steel.

Grade 405 stainless steel is soaked at 649-760°C (1200-1400°F) and then cooled in air.

Shielded fusion and resistance methods are recommended for welding grade 405 stainless steel.

Oxyacetylene welding is not suitable for this stainless steel grade. Hardening of grade 405 stainless steel

is controlled by the use of 405 Cb electrodes that contain columbium. Ductility of 405 stainless steel is

maximized by post weld annealing.

Grade 405 stainless steel is soaked at 817-871°C (1500-1600°F) and the temperature is then increased

to 1038-1121°C (1900-2050°F). Forging below 816°C (1500°F) is not recommended for this stainless steel

grade. Forging is followed by air cooling and finally annealing.

Usage of forming techniques enable grade 405 stainless steel to be easily spun, drawn and formed.

Standard methods are used to carry out the machiniability process for grade 405 stainless steel.

Grade 405 stainless steel can be hardened by soaking at 982-1010°C (1800-1850°F) and then oil quenched.

Other Grades:

201,202,21-4N,301,302,301L,303,303Se,304,304L,304H,304LN,304N,305,S38400,308,309,309S,310,310s,

316,316L,316H,316Ti,316N,316LN,317,317L,317LMN,317LN,321,321H,347,347H,S3100,S31803,S3205,

S32304,S31200,S31260,S32507,405,409,429,430,430F,434,444,403,410S,410,416,420,420F,431F,440A

440B,440C,440F,610,630,631,632,635,660,Alloy 200,Monel 400 ,Alloy K-500 ,Inconel 600 , Incconel 601,

Inconel 625 , Inconel 718 , Alloy 800 ,Alloy 800H,Alloy 800HT,Inconel 825,Alloy 276, Alloy 20, Alloy 59

| Tianjin Zhongyantiancheng Steel Co.,Ltd | ||||

| Commodity | Stainless Steel Flat Bar | |||

| Material | 405 | |||

| Standard | GB | JIS | ASTM/ASME | BS |

| 0Cr13Al | SUS 405 | 405 | 303S42 | |

| Chemical Composition | C | Mn | P | S |

| ≤0.08 | ≤1.00 | ≤0.040 | ≤0.030 | |

| Si | Cr | Al | Ni | |

| ≤1.00 | 11.5-14.5 | 0.10-0.30 | ≤0.50 | |

| Thickness | 3mm-30mm | |||

| Width | 10mm-300mm | |||

| Length | Produce as customers' request | |||

| Surface | No.1/HL/Birght | |||

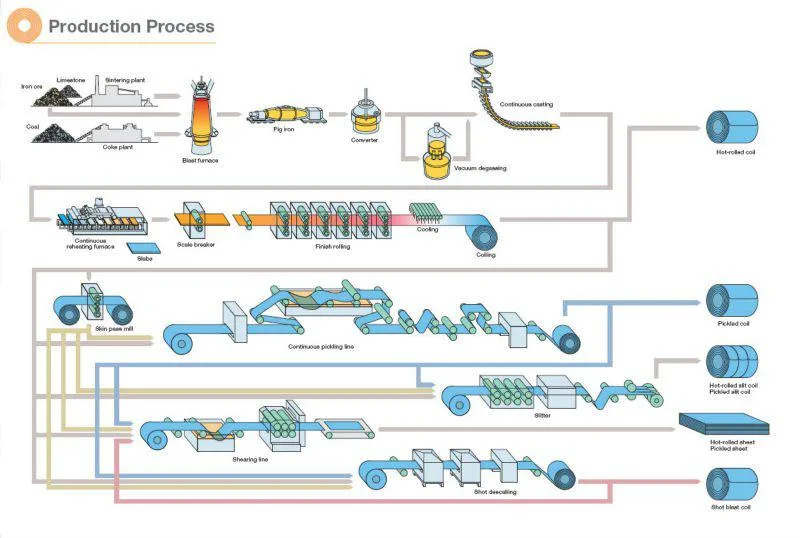

| manufacture | Hot Rolled/Cold Rolled | |||

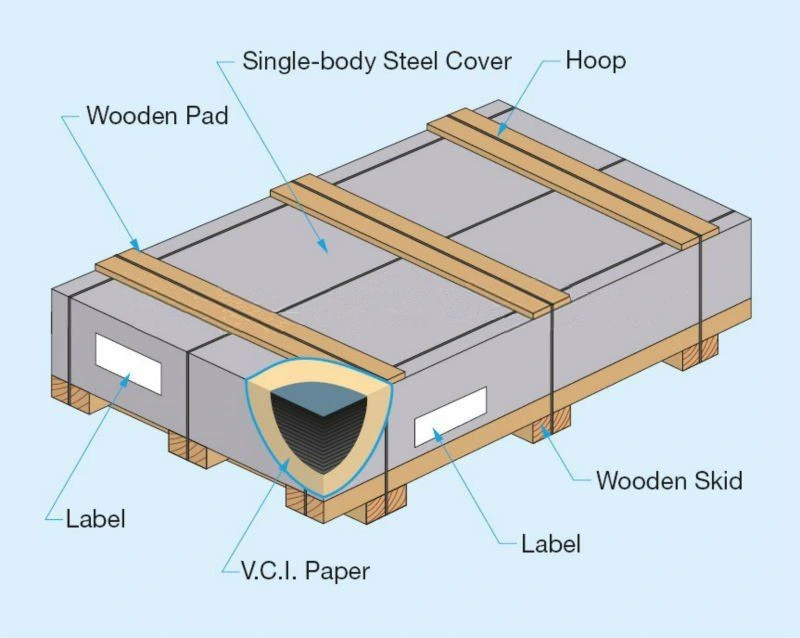

| Packing | Packed in bundles with standard export sea-worthy package | |||

| Delivery Time | Within 15 working days, according to customers' quantities | |||

| Quality | High Quality.SGS inspection is accepted if needed | |||

| Place of Origin | Tianjin | |||

| Productivity | 500 MT/Month | |||

| Payment | T/T,L/C | |||

| MOQ | 1 MT | |||

| Application | Foodstuff, Gas, metallurgy, biology, electron, chemical etc. | |||

4: Stainless Steel Plate/Flat Bar Package

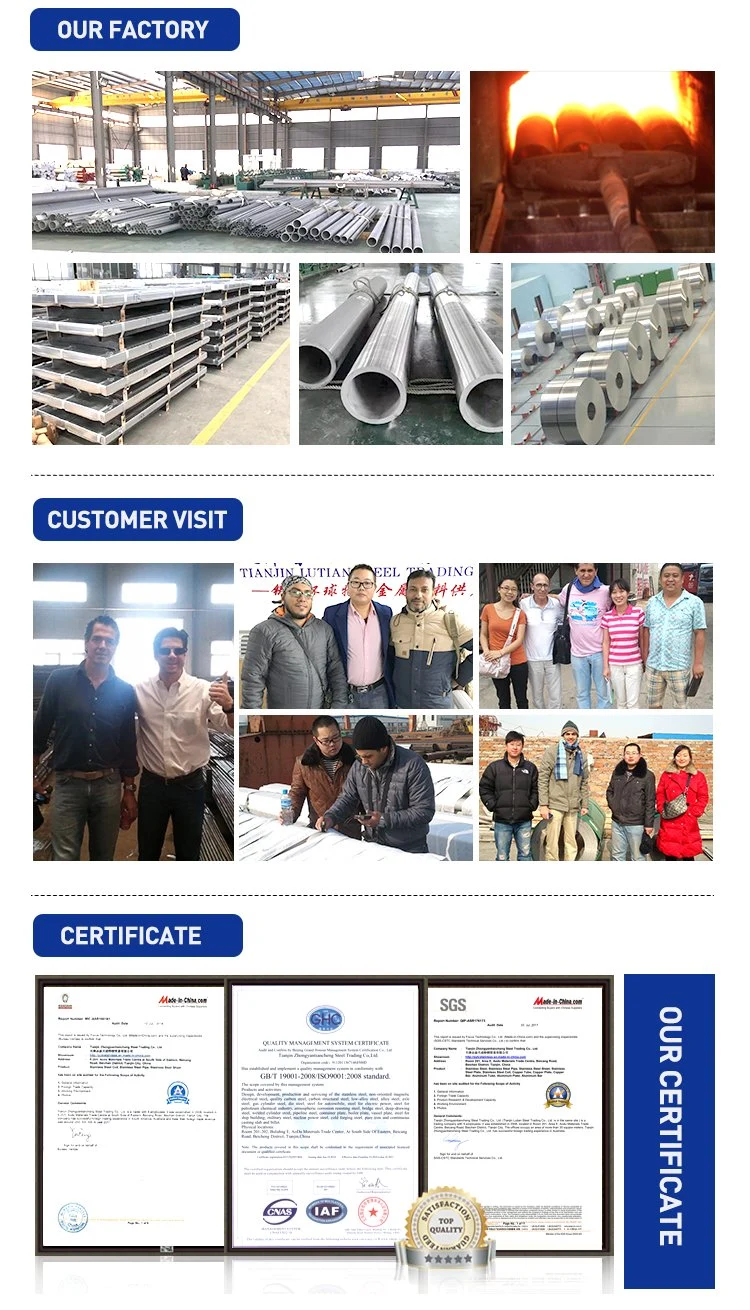

5: Company Introduction